About Engineering Technology Associates, Inc.

ETA’s engineering CAE-driven solutions (experience, innovation, and partnership) reduce the cost of product design and development by streamlining testing and prototyping processes. We strive towards complete virtual prototyping using our experience, products, and advanced technology.

As a true leader in CAE solutions, our expertise guarantees client success

Our wealth of simulation project experience paired with our strategic partnerships with global manufacturers and research institutes uniquely positions us to serve all our client’s needs.

Innovation-Driven

Drawing on 4-decades’ creativity when unorthodox solutions are called for.

Optimization/AI/ML

Making smarter, higher-quality products in reduced time.

Global Footprint

Providing engineering services and software tools globally.

Strategic Partnerships

Building solid relationships with OEMs, Tier-1 suppliers, and technology partners.

250

Employees worldwide

40+

Years of growth and success

4

CAE software products

40

Full vehicle CAE programs

Innovating across consulting, staffing and software solutions

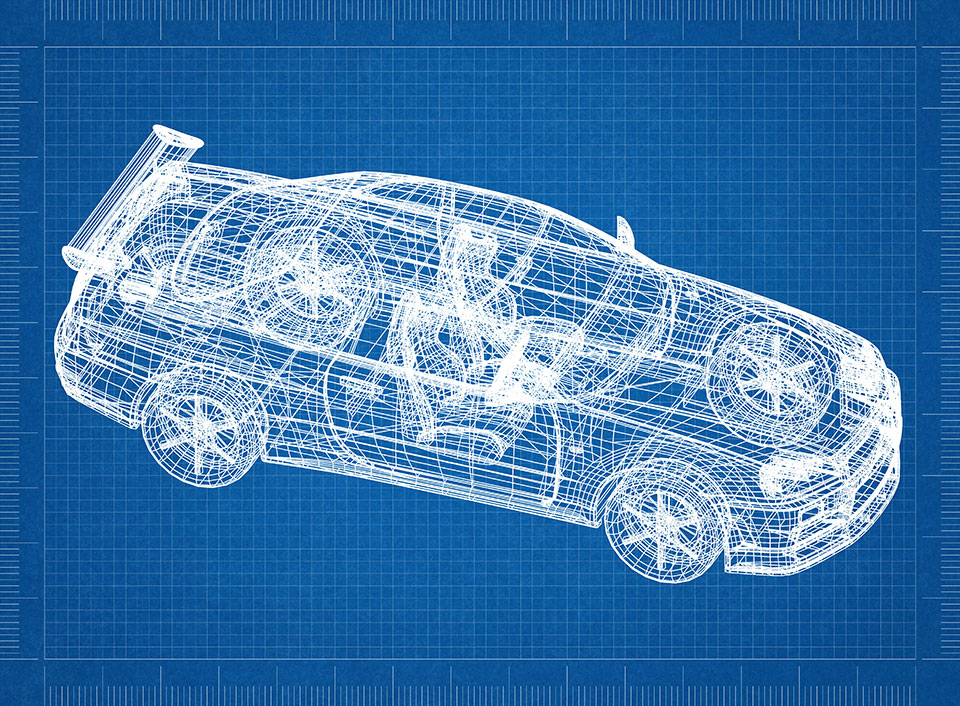

ETA serves the automotive, aerospace, and other key industries with every major aspect of CAE structural analysis.

CAE Software

ETA’s tools help design and validate your entire product development and sheet metal forming processes.

Engineering Solutions

As a full-service CAE virtual product development firm, ETA specializes in programs needing complex simulation solutions.

In-Client Services

Struggling to find qualified engineering talent? ETA’s In-Client Services connects you with top-tier applicants.

Driven by a common mission to advance CAE using technology and expertise

We are proud to be a global CAE solutions provider with over four decades of experience. Our value is strengthened by our team members, customer relationships, and partners.

Adaptable

We adapt to our client’s needs and environments, doing everything we can to help them succeed.

Transparent

We act with full transparency and trustworthiness.

Ever-Improving

We focus on growth and learning. Everything can be improved.

Team Players

We strive for a highly collaborative work environment.

Responsible

We’re all leaders taking the initiative to solve problems and get results.

Accountable

We deliver on our promises and deadlines, every time.

ETA’s continual growth, evolution, and innovation over 4 decades in the CAE space

1983 - 1993

ETA was founded in 1983 and within three years was established as a tier-one supplier to Ford, GM, and Chrysler, in addition to providing engineering services to OEMs and suppliers in US and Asia.

Our staff and services built a strong foundation for our next milestone: developing CAE software tools and training CAE engineers as required by the auto industry.

1993 - 2003

ETA becomes a CAE partner to the US & Asian OEMs and a supplier for full vehicle programs. We began developing software based on LSTC technologies. This decade marks 10 years of expertise in full vehicle CAE (crash/safety, durability, and NVH) and the development of software tools such as FEMB, VPG, and Dynaform. These tools enhanced product design and development and improved productivity as CAE entered a new era of virtual engineering.

Full Vehicle Programs

10+ years of service including 12 full vehicle programs covering all aspects of crash and safety

Expansion into Software

Developed software built to address industry needs for FE analysis (Pre/Post, durability, crash test environment, and stamping)

Establishment of CAE Partnerships

Established full vehicle development partnerships across Asia, Europe, and the US

International Growth

ETA is established as a full vehicle CAE consultant and international crash and safety expert in CAE simulation

2003 - 2013

ETA invests in advanced technologies such as light-weighting, advanced material, and process to reduce cost and time for product design and development. We innovated a new holistic, design-driven, patented optimization process called the Accelerated Concept To Product (ACP) Process.

Light-weighting

The ACP process provided a holistic optimization gateway to reduce product (structure) weight regardless of material

Advanced Material

Began using advanced high-strength steel, aluminum, and carbon fiber materials for light-weighting

Cost Optimiziation

ACP reduced the cost of material, consolidated the number of parts, and reduced the cost of tooling and manufacturing

Time Optimization

ACP reduced product design duration and time to market through CAD, design, and simulations

2013 - 2022

ETA leverages Big Data and AI/ML/ROM technologies, three decades of CAE experience, experience developing niche software solutions, and product and process optimization for faster and more accurate solutions.

Big Data, AI/ML

Leveraging AI/ML/ROM to reduce the duration of the traditional optimization process

Electric Vehicles

Providing faster and more accurate solutions using AI/ML and our advanced products such as VPG Suite and ACP OpDesign

Leadership and Board

Our diverse leadership team has an extensive background in Computer-Aided Engineering and technology allowing us to lead the way in product and service innovation. The team is spread out internationally, allowing for diverse business and industry insights that inform the direction of the company. As a result, ETA is able to provide more innovative software products and effective service and engineering placement solutions.

Global footprint of locations, partners, and providers

ETA has three offices internationally and a network of channel partners serving a global customer base.

ETA Offices

ETA North America

5445 Corporate Dr, Suite 301

Troy, United States 48098

ETA China

31E Shanghai Industrial Building, No. 18 North Xixi Road

Shanghai, China

Dynaform India Pvt. Ltd.

Sheriff Center, IndiQube Sapphire, St Mark’s Road, Bengaluru, Karnataka, India 560025

ETA Europe

ETA Europe,

Germany

Clients across a diverse range of sizes and industries

Suppliers

OEMs