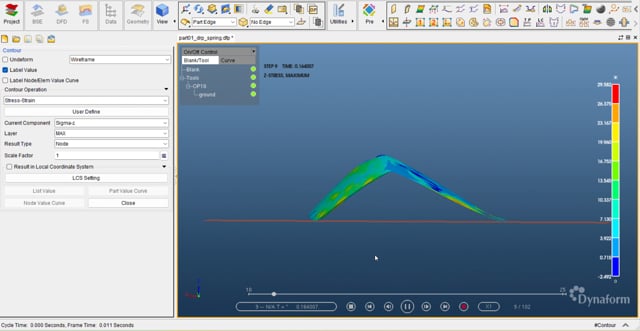

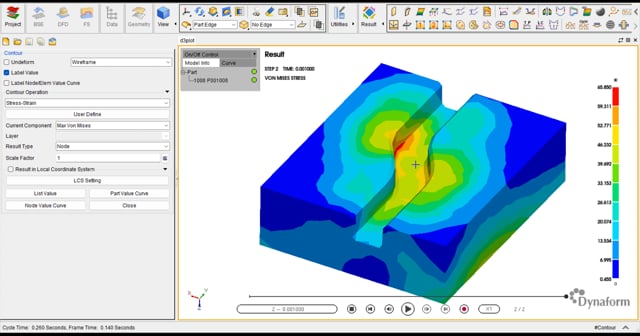

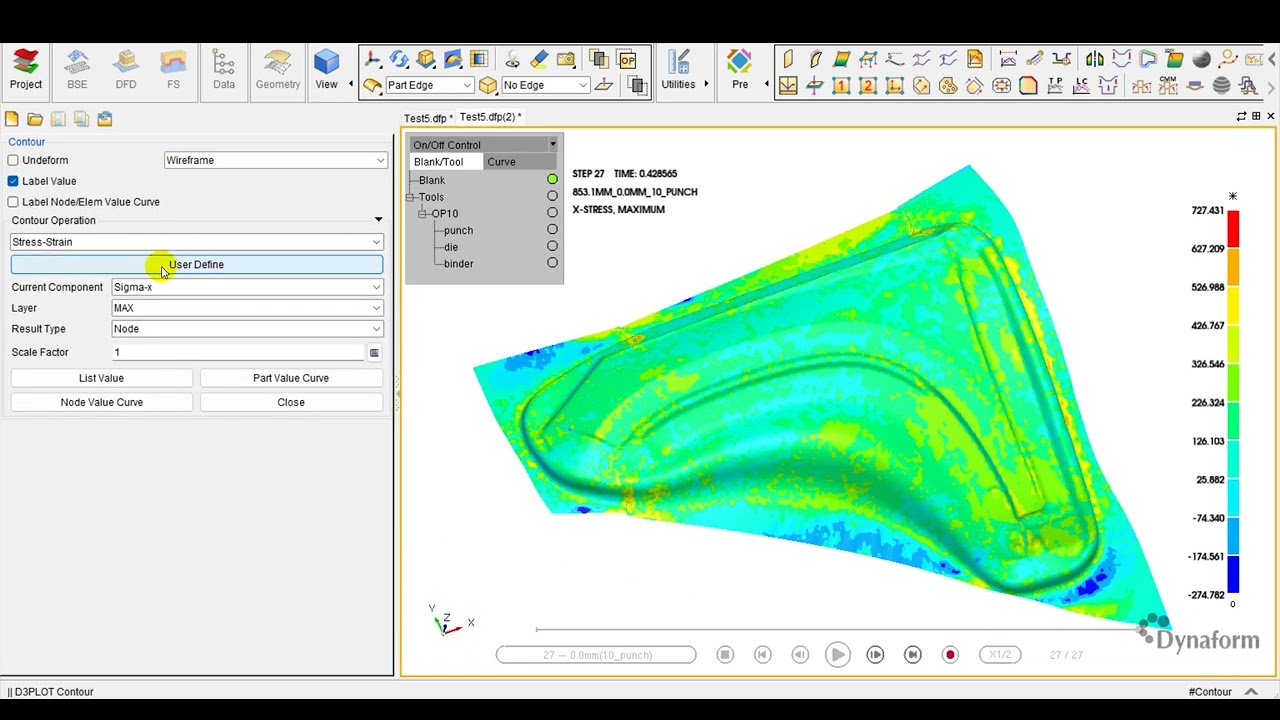

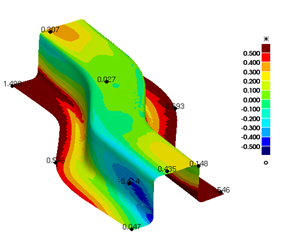

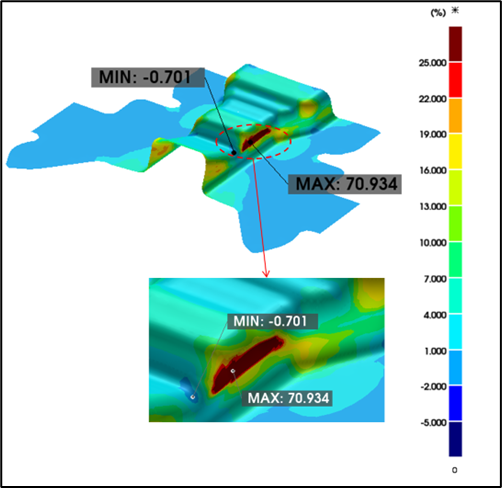

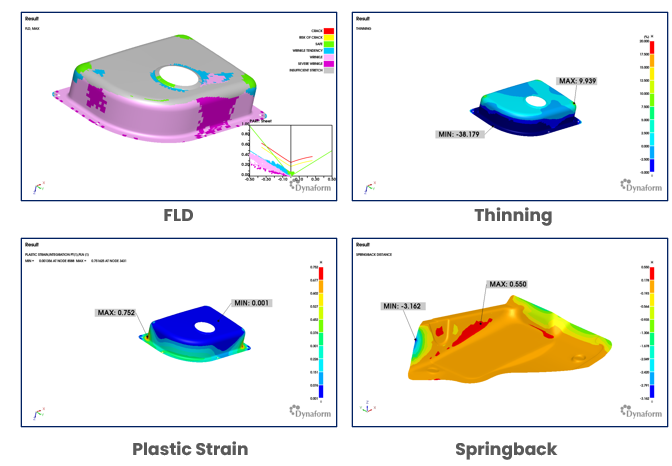

Description Struggling with springback in High-Strength Steel (HSS)? Learn proven springback compensation techniques and see how advanced sheet metal forming simulation accurately predicts and prevents costly defects. Introduction The automotive […]

Read Full Article

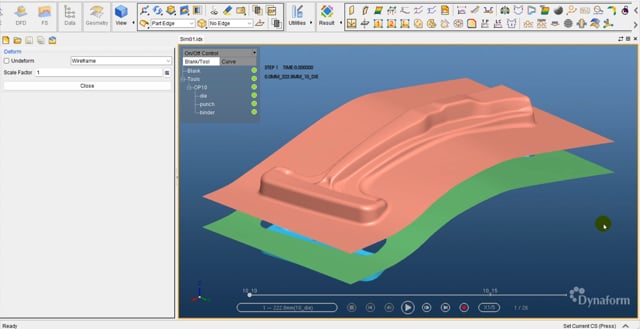

The gravity drop and transfer analysis feature has helped us minimize part deformation, ensuring better dimensional accuracy. It's been valuable in maintaining precision in our processes.

Feedback on Sheet Drop Test