May 16th, 2022

For years, engineers and tool designers have struggled to find comprehensive, accurate, and easy-to-use software for tube forming simulations. It’s difficult to save time and cut costs while also performing high-quality bending, pre-forming, hydroforming, trimming, and annealing tasks.

But that all changes with Dynaform 6.2

Dynaform 6.2 is the sixth-generation die system simulation solution. It provides a user-friendly and intuitive interface with a streamlined process design. The stamping simulation process is fully based on the actual stamping process, which requires less CAE knowledge, and minimum geometry and mesh operations.

With enhancements across nearly every area of Dynaform including Tube Forming, BSE, Geometry Manager, and more, Dynaform 6.2 is one of our greatest updates to date.

Learn more about all the new features in Dynaform 6.2, including newly enhanced capabilities, features, and functions in Tube Forming, Geometry Manager, BSE, Sheet Forming, and more in our walk-through webinar below.

So what’s new?

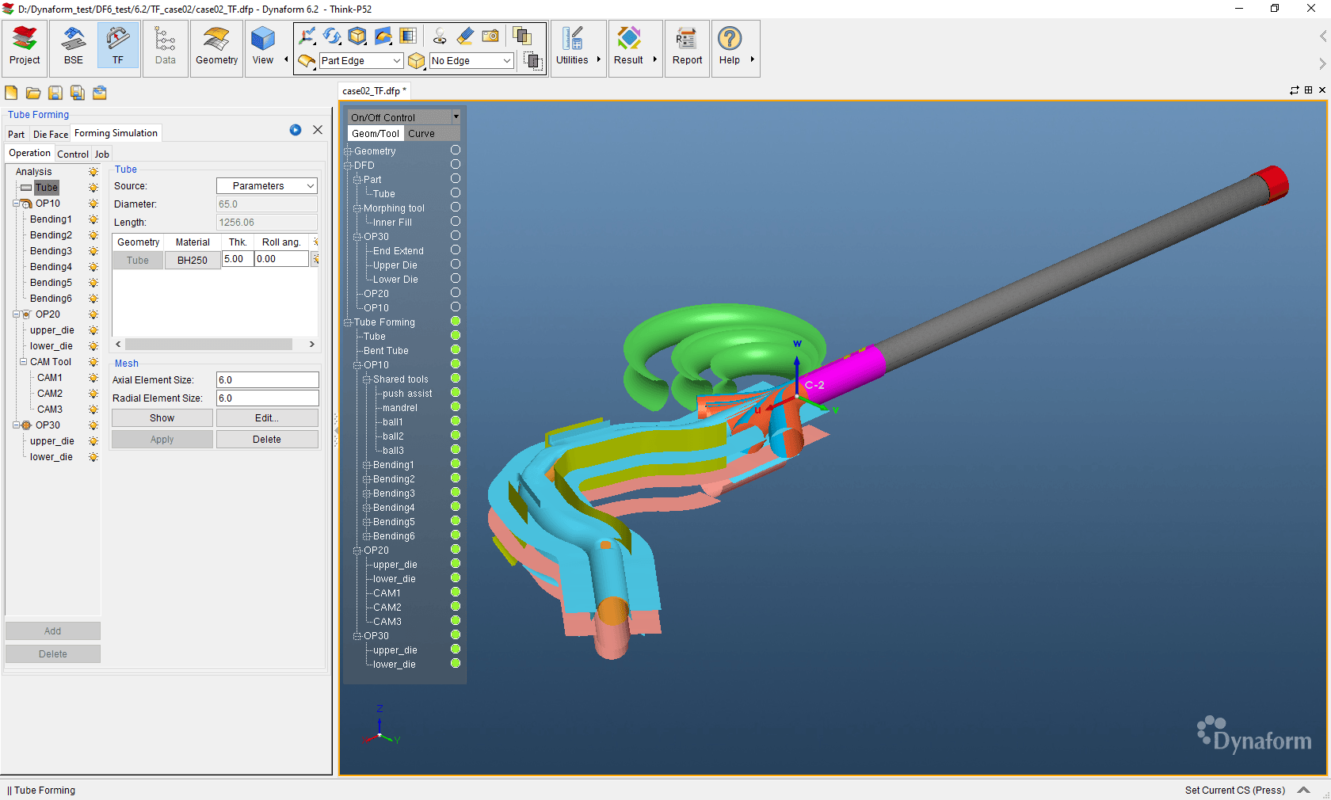

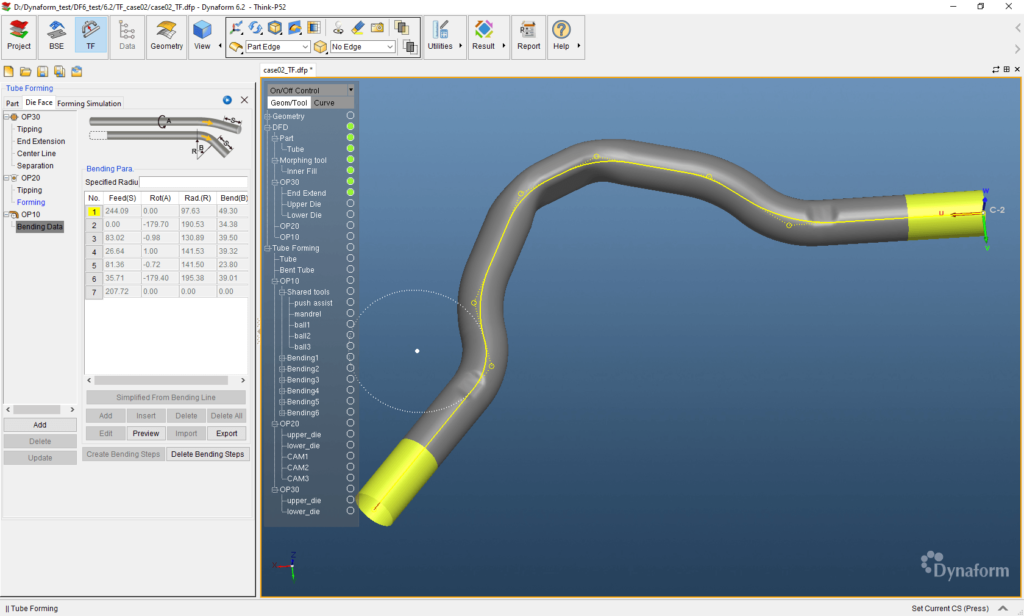

Significant Enhancements: Tube Forming Module

In the past, our customers have been vocal about needing more from Dynaform’s Tube Bending Module. That’s why we’re happy to announce that one of the most important and significant new features of Dynaform 6.2 is the newly-designed Tube Forming Module.

The module supports powerful simulations for nearly every area of tube forming, from tube bending, pre-forming, hydroforming definition, and more – and it’s all in one module.

Capabilities, Features, and Functions in Tube Forming

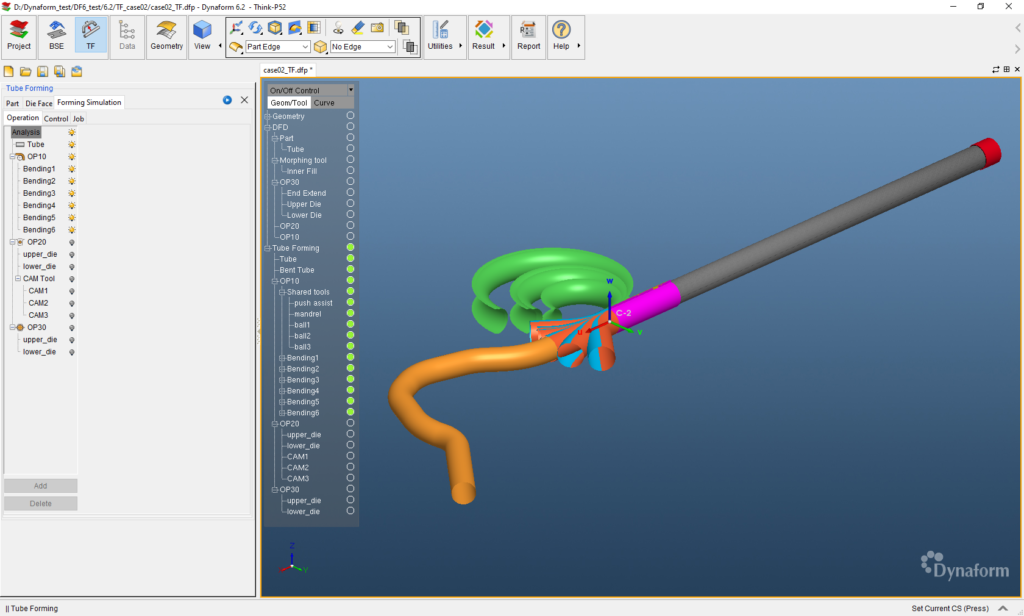

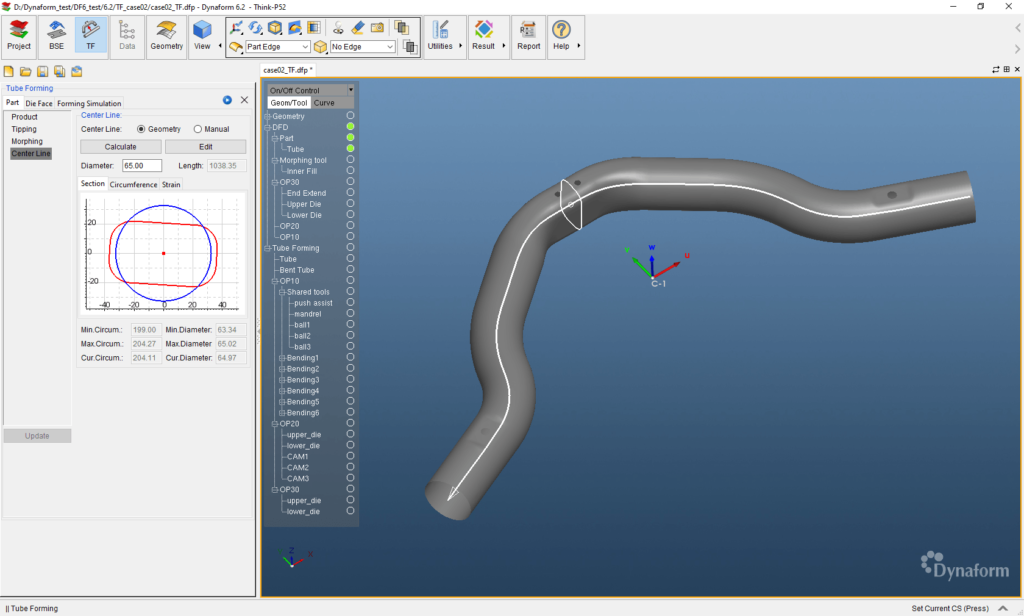

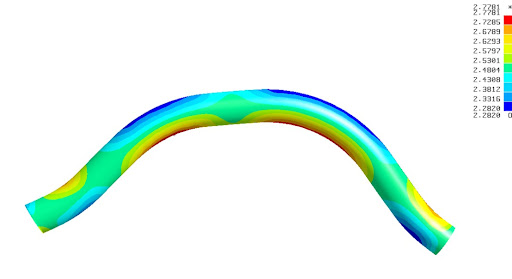

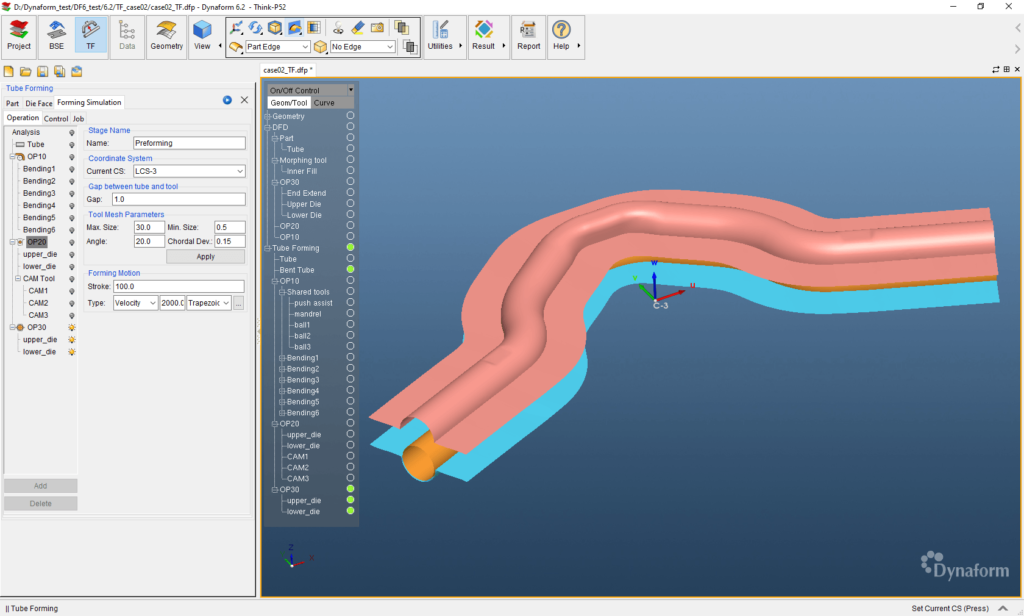

Dynaform’s Tube Forming simulation now supports the full process of multi-stage tube forming, including tube bending, pre-forming, hydroforming, trimming, and annealing. Moreover, it can accurately predict failures during the forming process – this includes wrinkles, cracks, spring back, and feasibility of hydroforming. Forming animations are also now supported.

Geometry & Automation Tools

Dynaform 6.2 also comes with a host of new geometry and automation tools.

The Tube Forming Module now has support for defining tube product geometry, editing the mesh of tube products, and identifying tube Start/End sides automatically. Center Lines can also be calculated automatically using the tube product geometry while maintaining the ability to define and edit center lines manually. The Center Line function now also supports the ability to show section cuts, circumference, and strain.

Once a base line is set, 6.2 also supports the ability to create simple pre-forming tools and to define tools to run pre-forming.

Bending Table Tools

Dynaform 6.2 also features many improvements to our Bending Table tools.

Dynaform’s bending table now supports editing, inserting, and deleting operations. It can simulate tube feeding, rotating, and bending simultaneously. It also supports seamless data exchange with a bending machine.

Users can now also import the bending table manually or automatically generate it from the center line. Our bending table generation algorithm improvements now serve to save users significant amounts of time generating tables.

Bending Process

The Bending Process in 6.2 can now be defined both automatically and manually. Moreover, both one-step and incremental solvers can be used in tube bending calculations.

The one-step solver can provide results in a very short time. The incremental solver can simulate the forming of feeding, rotating, and bending in a more accurate way. Say goodbye to overnight waits for checking the feasibility of product shape designs – they can now be completed within a few minutes to reveal obvious forming issues.

Hydroforming

Hydroforming in Dynaform 6.2 now supports comprehensive die face design including tube end extensions, centerline auto calculating, die separating line generation, mesh model separation based on separating lines, and more.

Instead of switching to CAD software to create the tools, users can finish almost all major FEA model reparation works in Dynaform, including tool generation, motion definition, mesh editing, and control cards editing.

No matter what process you’re using or which stage you’re focusing on, you can easily find the functions you’re looking for in the Tube Forming module.

Tube Forming is certainly exciting. But what about updates to Dynaform’s current modules?

Newly Enhanced Capabilities, Features, and Functions in Geometry Manager

Dynaform 6.2 presents many new updates to the Geometry Manager, including:

- Support for selecting Surface by Spread method.

- Support for exporting DXF format files.

- Support for adding the curve to the other layer.

- Thickness information for the solid part can now be saved to the database.

Newly Enhanced Capabilities, Features, and Functions in BSE

BSE has also seen great improvements with the release of 6.2, with four main improvements:

- Automatic thickness detection in Simple & Advanced mode.

- Three new options to select predefined mesh parameters: Fine, Regular, and Rough.

- Improved utilization of multi-row nesting.

- Improved report functions in nesting.

Newly Enhanced Capabilities, Features, and Functions in Post Process

6.2 introduces four main improvements to Dynaform’s Post Process tools:

- Support to create Boundary Lines.

- Improved shading speed in Post.

- Added the Coordinate manager.

- Support to show the current stage tools only.

- …and more.

Newly Enhanced Capabilities, Features, and Functions in ETA Report

ETA Report tools have also seen new improvements in 6.2:

- Automatic default step configuration for Springback Distance functions.

- Found the appropriate step according to the From Home distance for different result files.

- Automatic activation of the Plot ‘From Post’ button in the two result files.

- Widened the Edit Object dialog to display more information in the frame list.

- Support for the Springback Distance function.

Dynaform 6.2 is the answer to the industry’s need for comprehensive, accurate, and easy-to-use software for tube forming simulations, and we’re excited to see all the ways you’ll utilize it.

Learn more about all the new features in Dynaform 6.2, including newly enhanced capabilities, features, and functions in Tube Forming, Geometry Manager, BSE, Sheet Forming, and more in our walk-through webinar.